Hydrogen from Methane Pyrolysis

This blog is taken from the post Hydrogen from Methane Pyrolysis.

Pyrolysis is a well-established process in which an organic material is heated to a high temperature in the absence of oxygen. Depending on the source materials used, the products from the reaction consist of organic materials and solid carbon in the form of char/charcoal/carbon black.

Charcoal Burners

Credit: travelfranceonline.com..

The principle of pyrolysis stretches back centuries. Men called charcoal burners (charbonniers in France) burned wood in a large pile covered by turf. The light hydrocarbons (the material that makes flames when the wood is burned normally) are driven off from the top of the pile, leaving just the charcoal. The charcoal so produced generates much higher temperatures than wood. Hence it can be used for early industrial processes, such as the smelting of iron.

Methane Pyrolysis

In the case of methane pyrolysis, the products are hydrogen and elemental carbon, according to the following equation.

CH4 ⇌ C + 2H2

High temperature (1065°C) is needed to drive the reaction to the right hand side of the equation. (The use of catalysts such as nickel allows this temperature to be reduced by 200°C. or more) A description of the different types of methane pyrolysis process is provided by Schneider at al. (Schneider, 2020)1.

The calorific value of the hydrogen is about 60% of the methane used due to the removal of its carbon.

The process is endothermic, i.e., it requires an energy input. However, the heat of combustion of the hydrogen produced is much higher than the heat required for the pyrolysis reaction. Therefore heat for the reaction can be obtained by using some of the hydrogen just produced. Alternatively, the heat required can be supplied electricity generated by wind or solar.

The hydrogen that is produced is “green”. The high quality produced carbon can be used in the manufacture of a wide range of products such as high quality graphitic carbon/carbon fibers and tubes. If the carbon is simply buried then the overall process becomes a form of direct air carbon capture and storage (DACCS).

One of the principal drawbacks to the pyrolysis process in its present form is the need for high temperatures. This is why research into catalysts that will allow for much lower temperatures is so important.

Economics

Hydrogen will be a foundational fuel and industrial feedstock in a Net Zero world. This does not mean that it will completely replace fossil fuels, but it will be an important piece of the Net Zero puzzle.

The economics of hydrogen use are complex, but three issues are worth consideration. They are,

- Choice of technology;

- The price of natural gas; and

- Stranded assets.

Technology

The economics of methane pyrolysis need to be compared with other methods of hydrogen manufacture. This is a topic that we will cover in future posts.

Natural Gas Price

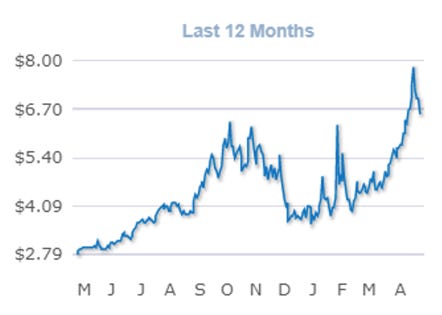

Energy prices have climbed steeply over the course of the last twelve months. Therefore, any hydrogen-producing process, including methane pyrolysis, that is natural gas based will be relatively expensive compared to the electrolysis of water using wind or solar power.

Source: Bar Chart Solutions

Stranded Assets

An economic issue that many oil companies face is that of stranded assets. These companies have invested massive amounts of money over the years in finding and developing oil and gas wells. Any technology that allows them to produce clean energy while using these assets is very attractive.

Methane (natural gas) pyrolysis meets this requirement. The natural gas that is already in place can be used to make hydrogen and carbon, which can be disposed of safely and easily.

Carbon Sequestration

The carbon produced in the pyrolysis process can be used in a wide variety of industrial processes. Even if the carbon cannot be sold for industrial purposes it can be sequestered, i.e., disposed of underground. In other words the pyrolysis process is a Carbon Capture & Sequestration (CC&S) technology. One of the difficulties with most CC&S processes is that the CO2 — being a gas — is difficult to store. It can be compressed and injected into old gas wells, but this is expensive and it is difficult to ensure the long-term integrity of the storage. The solid carbon produced by methane pyrolysis does not suffer from this drawback. Being solid it can be transported to its final disposal site, such as a disused coal mine.

Scale

Although methane pyrolysis is a proven technique for making hydrogen it has not yet been commercialized. As with so many other suggestions for addressing the climate crisis, the question is not, “Can it be done?”, but, “Can it be implemented economically, at scale, within the next 28 years?”

With regard to methane pyrolysis the answer is not better than “maybe”. The technology is still being developed, and the economics of the process depend on the development of a catalyst that allows the pyrolysis reaction to take place at relatively low temperatures. Currently the catalysts that are being tested lose their activity in a short period of time (a few weeks at most). Until ways are found of extending catalyst life, or regenerating catalyst economically, methane pyrolysis does not appear to be a viable option for quick scale up.